- Home

- Taxonomy

- Term

- 2024

ಸಣ್ಣ ಮಾರ್ಪಾಡುಗಳು- ನಾಟಕೀಯವಾಗಿ ಅಧಿಕಗೊಳ್ಳುವ ಪೀಜೋಸೆರಾಮಿಕ್ ಗಳ ಪರಿಣಾಮಕಾರಿತ್ವ

09 ಜನವರಿ 2025

-ರಂಜಿನಿ ರಘುನಾಥ್

ಸಾಮಾನ್ಯ ಬಳಕೆಯ ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ಪಿಂಗಾಣಿ ವಸ್ತುಗಳ ಪರಿಣಾಮಕಾರಿತ್ವವನ್ನು, ಅವುಗಳ ದಪ್ಪವನ್ನು ಕಡಿಮೆಗೊಳಿಸುವ ಮೂಲಕ ಹಾಗೂ ತಯಾರಿಕೆ ವೇಳೆ ಅನಿರೀಕ್ಷಿತವಾಗಿ ಉಂಟಾಗುವ ‘’ಪರಮಾಣು ವ್ಯತ್ಯಯ’ಗಳನ್ನು ತಪ್ಪಿಸುವ ಮೂಲಕ ನಾಟಕೀಯವೆನ್ನಿಸುವ ರೀತಿಯಲ್ಲಿ ಹೆಚ್ಚಿಸಬಹುದು ಎಂಬುದನ್ನು ಭಾರತೀಯ ವಿಜ್ಞಾನ ಸಂಸ್ಥೆಯ (ಐ.ಐ.ಎಸ್.ಸಿ) ತಜ್ಞರು ಸಹಭಾಗಿತ್ವದ ಸಂಶೋಧನೆಯಲ್ಲಿ ಕಂಡುಕೊಂಡಿದ್ದಾರೆ. ಈ ಕುರಿತ ಅಧ್ಯಯನ ವರದಿಯು ‘ನೇಚರ್’ ನಿಯತಕಾಲಿಕದಲ್ಲಿ ಪ್ರಕಟವಾಗಿದೆ.

ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ವಸ್ತುಗಳು ವಿದ್ಯುತ್ ಕ್ಷೇತ್ರದ ಪ್ರಭಾವಕ್ಕೆ ಒಳಪಡಿಸಿದಾಗ ವಿರೂಪಗೊಳ್ಳುತ್ತವೆ (ಹಿಗ್ಗುವುದು ಅಥವಾ ಕುಗ್ಗುವುದು). ತಮ್ಮ ಈ ಗುಣದಿಂದಾಗಿ ಅವು ಹಲವಾರು ಬಗೆಯ ಆನ್ವಯಿಕತೆಗಳಿಗೆ ಸೂಕ್ತವಾಗುತ್ತವೆ. ಹೀಗಾಗಿ, ಆಸ್ಪತ್ರೆಗಳಲ್ಲಿ ಅಲ್ಟ್ರಾಸೌಂಡ್ ಇಮೇಜಿಂಗ್ ನಿಂದ ಹಿಡಿದು ಗುರಿ ನಿರ್ದೇಶಿತ ಕ್ಷಿಪಣಿಗಳಲ್ಲಿ ಆಕ್ಚುಯೇಟರ್ ಗಳವರೆಗೆ ಇವುಗಳಿಂದ ಅನೇಕ ಉಪಯೋಗಗಳಿವೆ. ಪ್ರಯೋಗಾಲಯದಲ್ಲಿ ಅಭಿವೃದ್ಧಿಪಡಿಸಿದ ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ನ ಸಿಂಗಲ್ ಸ್ಫಟಿಕಗಳು ದೊಡ್ಡ ಪ್ರಮಾಣದ ‘ಸಮಾನಾಂತರ ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್’ (1%ಗಿಂತ ಹೆಚ್ಚು) ತೋರ್ಪಡಿಸುತ್ತವೆ. ಇದು ವಸ್ತುವು ವಿದ್ಯುತ್ ಕ್ಷೇತ್ರದ ದಿಕ್ಕಿನಲ್ಲಿ ಅದು ವಿರೂಪಗೊಳ್ಳುವ ಪ್ರಮಾಣವನ್ನು ತೋರಿಸುವ ಮಾಪನಾಂಕವಾಗಿರುತ್ತದೆ. ಆದರೆ, ಇಂತಹ ವಸ್ತುಗಳು ತುಂಬಾ ಅಪರೂಪ. ಜೊತೆಗೆ, ಇಂತಹ ‘ಏಕಸ್ಫಟಿಕ’ಗಳ ದೊಡ್ಡ ಪ್ರಮಾಣದ ಉತ್ಪಾದನೆಯು ದುಬಾರಿ ವೆಚ್ಚದ ಬಾಬ್ತಾಗಿರುತ್ತದೆ. ಆದ್ದರಿಂದ, ಅವುಗಳನ್ನು ನಿರ್ದಿಷ್ಟ ಆನ್ವಯಿಕತೆಗಳಲ್ಲಿ ಮಾತ್ರ ಬಳಸಲಾಗುತ್ತದೆ. ಬಹುತೇಕ ವಾಣಿಜ್ಯಿಕ ಆನ್ವಯಿಕತೆಗಳಿಗೆ ಸಾಧಾರಣ ಬೆಲೆಯ ಪಾಲಿಕ್ರಿಸ್ಟಲೈನ್ ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ಪಿಂಗಾಣಿ ವಸ್ತುಗಳನ್ನು ಉಪಯೋಗಿಸಲಾಗುತ್ತದೆ. ಆದರೆ, ಇವು ತೋರುವ ‘ಸಮಾನಾಂತರ ಸ್ಟ್ರೇನ್’ ಪ್ರಮಾಣವು ತುಂಬಾ ಕಡಿಮೆ (0.2-0.4%) ಪ್ರಮಾಣದಲ್ಲಿರುತ್ತದೆ.

“ಪಾಲಿಕ್ರಿಸ್ಟಲೈನ್ ಸೀಸ ರಹಿತ ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ವಸ್ತುಗಳು ತೋರ್ಪಡಿಸುವ ಗರಿಷ್ಠ ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್ 0.7% ಆಗಿರುತ್ತದೆ” ಎನ್ನವು ಐ.ಐ.ಎಸ್.ಸಿ. ಮಟೀರಿಯಲ್ಸ್ ಎಂಜಿನಿಯರಿಂಗ್ ವಿಭಾಗದ ಹಳೆಯ ಪಿಎಚ್.ಡಿ. ವಿದ್ಯಾರ್ಥಿ ಹಾಗೂ ಅಧ್ಯಯನದ ಮೊದಲ ಲೇಖಕರಾದ ಗೋವಿಂದ ದಾಸ್ ಅಧಿಕಾರಿ ಅವರು, “ಈ ಪ್ರಮಾಣವನ್ನು ಹೆಚ್ಚಿಸುವುದು ನಮ್ಮ ಉದ್ದೇಶ” ಎಂದೂ ಹೇಳುತ್ತಾರೆ.

ಪೀಜೋಸೆರಾಮಿಕ್ ವಸ್ತುವಿನ ಪ್ರತಿಯೊಂದು ‘ಗ್ರೇನ್’ (ಕಣಗಳ ರಚನೆ) ಕೂಡ ಡೊಮೇನ್ಸ್ ಎಂದು ಕರೆಯಲಾಗುವ ಸ್ವಯಂ ಧ್ರುವೀಯ ವಲಯಗಳನ್ನು ಹೊಂದಿರುತ್ತದೆ. ಇವು ಏಕಕಾಲಕ್ಕೆ ವಿದ್ಯುತ್ ಕ್ಷೇತ್ರದೆಡೆಗೆ ತಮ್ಮ ವಾಲುವಿಕೆಯ ದಿಕ್ಕನ್ನು ಬದಲಾಯಿಸುತ್ತವೆ. ಹೀಗಾದಾಗ, ಆ ವಸ್ತುವಿಗೆ ವಿರೂಪತೆ ಉಂಟಾಗುತ್ತದೆ. ವಸ್ತುವಿನ ಮೇಲ್ಮೈಗೆ ಸನಿಹದಲ್ಲಿರುವ ‘ಗ್ರೇನ್’ಗಳು ಹೆಚ್ಚು

ಸ್ವತಂತ್ರವಾಗಿರುವುದರಿಂದ ಅವುಗಳ ವಿರೂಪತೆಯ ಪ್ರಮಾಣವೂ ಅಧಿಕವಿರುತ್ತದೆ. ಆದರೆ, ಆಳದ ಕಣಗಳು ಇತರ ಕಣಗಳ ನಡುವೆ ಬಿಗಿಯಾಗಿ ಬಂದಿಯಾಗಿರುವುದರಿಂದ ವಿರೂಪಗೊಳ್ಳಲು ಪ್ರಯಾಸಪಡುತ್ತವೆ. ಸಾಮಾನ್ಯ ಬಳಕೆಯಲ್ಲಿರುವ ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ಬಿಲ್ಲೆಗಳಲ್ಲಿ (10 ಮಿ.ಮೀ. ವ್ಯಾಸ ಹಾಗೂ 1 ಮಿ.ಮೀ. ದಪ್ಪ) ಬಹುತೇಕ ‘ಗ್ರೇನ್’ಗಳು ವಿರೂಪಗೊಳ್ಳುವ ಪ್ರಮಾಣ ಅತ್ಯಲ್ಪವಾಗಿರುತ್ತದೆ. ಇದರಿಂದ, ಒಟ್ಟಾರೆ ‘ಸಮಾನಾಂತರ ಸ್ಟ್ರೇನ್’ ಕಡಿಮೆ ಇರುತ್ತದೆ ಎಂಬುದು ಮಟೀರಿಯಲ್ಸ್ ಎಂಜಿನಿಯರಿಂಗ್ ವಿಭಾಗದ ಪ್ರೊಫೆಸರ್ ಹಾಗೂ ಅಧ್ಯಯನದ ಸಹಲೇಖಕರಾದ ರಾಜೀವ್ ರಂಜನ್ ಅವರ ವಿವರಣೆ.

ವ್ಯಾಪಕವಾಗಿ ಪ್ರಚಲಿತವಿರುವ ಪಿ.ಜಡ್.ಟಿ. (ಲೆಡ್ ಜೆರ್ಕೊನೇಟ್ ಟೈಟಾನೇಟ್) ಪೀಜೋಸೆರಾಮಿಕ್ ನ ಗಾತ್ರ ಹಾಗೂ ಆಕಾರವನ್ನು ಮಾರ್ಪಡಿಸುವಾಗ, ವರ್ತುಲಾಕಾರದ ಪಿ.ಜಡ್.ಟಿ. ಬಿಲ್ಲೆಯ ದಪ್ಪವನ್ನು 0.7 ಮಿ.ಮೀ.ನಿಂದ 0.2 ಮಿ.ಮೀ.ಗೆ ಕಡಿಮೆಗೊಳಿಸಿದಾಗ, ಅದರ ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್ 0.3%ದಿಂದ 1%ಗೆ ವೃದ್ಧಿಗೊಂಡಿದ್ದನ್ನು ರಂಜನ್ ಅವರ ತಂಡದವರು ಗಮನಿಸಿದರು..

ಇದರಿಂದ ಕುತೂಹಲಗೊಂಡ ತಜ್ಞರು ಯೂರೊಪಿಯನ್ ಸಿಂಕ್ರೊಟಾನ್ ರೇಡಿಯೇಷನ್ ಫೆಸಿಲಿಟಿಯ (ಇ.ಎಸ್.ಆರ್.ಎಫ್) ವಿಜ್ಞಾನಿಗಳ ಸಹಭಾಗಿತ್ವದಲ್ಲಿ ಎಕ್ಸ್-ರೇ ಡಿಫ್ರ್ಯಾಕ್ಷನ್ ಪ್ರಯೋಗಗಳನ್ನು ನಡೆಸಿದರು. ‘ಗ್ರೇನ್’ಗಳ ದಪ್ಪವನ್ನು ಕಡಿಮೆಗೊಳಿಸಿದಾಗ ಧ್ರುವೀಯ ವಲಯಗಳ ಬದಲಾವಣೆಯು ಗಣನೀಯವಾಗಿ ಜಾಸ್ತಿಯಾಗುವುದು ಕಂಡುಬಂದಿತು “ಅದು 02 ಮಿ.ಮೀ. ಇದ್ದಾಗ ಮೇಲ್ಮೈ ಸನಿಹದಲ್ಲಿದೆ ಎಂದು ಪರಿಭಾವಿಸುವ ವಲಯಗಳು ಉತ್ತಮ ಪ್ರಮಾಣದಲ್ಲಿ ಬದಲಾಗುತ್ತವೆ” ಎಂಬುದು ರಂಜನ್ ಅವರ ವಿವರಣೆ. “ಅಂದರೆ, 0.3% ಸ್ಟ್ರೇನ್ ಇರುವ 1 ಮಿಮೀ. ಪಿಂಗಾಣಿ ಬದಲಿಗೆ 0.2 ಮಿಮೀನ ಬಿಲ್ಲೆಗಳನ್ನು ಒಂದರ ಮೇಲೊಂದು ಪೇರಿಸಿದರೆ ಅದರ ‘ಸ್ಟ್ರೇನ್ ಸಾಮರ್ಥ್ಯ[ವನ್ನು ಹೆಚ್ಚಿಸಬಹುದು” ಎಂದಾಗುತ್ತದೆ.

ಬಹುತೇಕ ವಾಣಿಜ್ಯಿಕ ಅತ್ಯಾಧುನಿಕ ಪೀಜೋಎಲೆಕ್ಟ್ರಿಕ್ ವಸ್ತುಗಳಲ್ಲಿ ಸೀಸದ ಅಂಶವಿರುತ್ತದೆ. ಈ ಸೀಸವು ಕ್ಯಾನ್ಸರ್ ಕಾರಕವಾಗಿದ್ದು, ಪರಿಸರಕ್ಕೆ ಹಾನಿಕಾರಕವಾಗಿರುತ್ತದೆ. ಕೆಲವು ಸೀಸ ರಹಿತ ಪೀಜೋಸೆರಾಮಿಕ್ ಗಳ ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್ 1%ಗಿಂತ ಹೆಚ್ಚಿನ ಮೌಲ್ಯಾಂಕನವಿದೆ ಎಂಬ ವರದಿಗಳು ದೋಷಪೂರಿತ ಎಂಬದನ್ನು ಕೂಡ ತಂಡದವರು ದೃಢಪಡಿಸಿಕೊಂಡಿದ್ದಾರೆ. ಸುಮಾರು ಮೂರು ವರ್ಷಗಳ ಹಿಂದೆ ಗೋವಿಂದ ದಾಸ್ ಅಧಿಕಾರಿಯವರು ಸೋಡಿಯಂ ಬಿಸ್ಮತ್ ಟೈಟಾನೇಟ್ ಎಂಬ ಸೀಸ ರಹಿತ ಪೀಜೋಸೆರಾಮಿಕ್ ವಸ್ತುವನ್ನು ಪರೀಕ್ಷಿಸುತ್ತಿದ್ದ ಸಂದರ್ಭದಲ್ಲಿ ಅದರ ‘ಸ್ಟ್ರೇನ್ ಮ್ಯಾಲಾಂಕನ’ವು 1.5%ರಷ್ಟಿರುವುದು ಅನಿರೀಕ್ಷಿತವಾಗಿ ಕಂಡುಬಂತು. ಆಗ ನನಗೆ ಆದ ಖುಷಿ ಅಷ್ಟಿಷ್ಟಲ್ಲ. ಆದರೆ ಆ ಸಂತೋಷ ದೀರ್ಘಕಾಲ ಉಳಿಯಲಿಲ್ಲ. ಆ ವಸ್ತುವು ಸಮಾನಾಂತರವಾಗಿ ಹಿಗುವುದು ಅಥವಾ ಕುಗ್ಗುವುದು ಕಂಡುಬರಲಿಲ್ಲ. ಬದಲಿಗೆ, ಅದು ಬಾಗುವುದು ಕಂಡುಬಂತು. ಹೀಗೆ ಬಾಗುವುದು ಸಂಪೂರ್ಣ ಬೇರೆಯೇದೇ ವಿದ್ಯಮಾನವಾಗಿರುತ್ತದೆ. ಅಧಿಕ ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್ ಮೌಲ್ಯವಿರುವ ಇತರ ಹಲವು ವಸ್ತುಗಳನ್ನು ಪರೀಕ್ಷಿಸಿದಾಗಲೂ, ಅವು ಸಮಾನಾಂತರ ವಿರೂಪವಲ್ಲ; ಬದಲಿಗೆ ಬಾಗುವಿಕೆ ಎಂಬುದು ದೃಢಪಟ್ಟಿತು.

ಈ ‘ಬಾಗುವಿಕೆ’ಗೆ ಸಂಭಾವ್ಯ ಕಾರಣವನ್ನು ಕೂಡ ತಂಡದವರು ಕಂಡುಹಿಡಿದರು. ಪೀಜೋಸೆರಾಮಿಕ್ ಗಳನ್ನು ತಯಾರಿಸುವಾಗ ಸಾಮಾನ್ಯವಾಗಿ ಅವನ್ನು 1,100ರಿಂದ 1,300 ಡಿಗ್ರಿ ಸೆಲ್ಸಿಯಸ್ ಉಷ್ಣತೆಗೆ ಬಿಸಿಗೊಳಿಸಲಾಗುತ್ತದೆ. ಹೀಗಾದಾಗ, ‘ಆಕ್ಸಿಜನ್ ವೇಕೆನ್ಸೀಸ್’ (ಆಮ್ಲಜನಕ ನಿರ್ವಾತಗಳು) ಎಂಬ ಧನ ವಿದ್ಗುದಾವಿಷ್ಟ ನ್ಯೂನತೆಗಳು ರೂಪುಗೊಳ್ಳುತ್ತವೆ. ವಿದ್ಯುತ್ ಕ್ಷೇತ್ರದ ಪ್ರಭಾವದಲ್ಲಿ ಈ ‘ವೇಕೆನ್ಸಿ’ಗಳು ಋಣ ವಿದ್ಯುದಾವಿಷ್ಟ ಎಲೆಕ್ಟ್ರೋಡ್ ನೆಡೆಗೆ ಸಾಗುತ್ತವೆ. ಋಣಾವಿಷ್ಟ ಬದಿಗೆ ಹತ್ತಿರದಲ್ಲಿರುವ ವಲಯಗಳು ಈ ‘ವೇಕೆನ್ಸಿ’ಗಳ ಹಿಡಿತಕ್ಕೆ ಒಳಪಡುವುದರಿಂದ ಅವುಗಳಿಗೆ ಬದಲಾವಣೆಗೊಳ್ಳಲು ಆಗುವುದಿಲ್ಲ. ಆದರೆ, ಧನಾವಿಷ್ಟ ಬದಿಯ ವಲಯಗಳು ಹೆಚ್ಚು ಬದಲಾವಣೆಗೊಳ್ಳಬಲ್ಲವು” ಎಂಬುದು ರಂಜನ್ ಅವರ ವಿವರಣೆ. ಈ ಅಸಮತೋಲನವು ವಸ್ತುವು ಬಾಗುವಂತೆ ಮಾಡುತ್ತದೆ. ರಂಜನ್ ಅವರ ಪ್ರಕಾರ, ಇದನ್ನೇ ಸಾಮಾನ್ಯ ಮಾಪನದ ವೇಳೆ ಸಮಾನಾಂತರ ವಿರೂಪತೆ ಎಂದು ತಪ್ಪಾಗಿ ಭಾವಿಸುವ ಸಾಧ್ಯತೆ ಇರುತ್ತದೆ.

“’ಎಲ್ಲಾ ಸೀಸ ರಹಿತ ಪೀಜೋಸೆರಾಮಿಕ್ ಗಳಲ್ಲಿ ಒಂದೊಮ್ಮೆ ‘ಆಕ್ಸಿಜನ್ ವೇಕೆನ್ಸಿ’ಗಳನ್ನು ತಗ್ಗಿಸುವುದು ನಮಗೆ ಸಾಧ್ಯವಾಗುವುದಾದರೆ ‘ಸಮಾನಾಂತರ ಸ್ಟ್ರೇನ್’ ಅನ್ನು ಪಿ.ಜಡ್.ಟಿ.ಯಲ್ಲಿ ಕಂಡುಬರುವಂತೆ 1% ಗೆ ಅಥವಾ ಅದಕ್ಕಿಂತ ಹೆ್ಚಿನ ಪ್ರಮಾಣಕ್ಕೆ ಹೆಚ್ಚಿಸಬಹುದು” ಎಂದು ಅವರು ಮುಂದುವರಿಸುತ್ತಾರೆ. ಸೀಸ ರಹಿತ ಪೀಜೋಸೆರಾಮಿಕ್ ವಸ್ತುಗಳಲ್ಲಿ ‘ಆಕ್ಸಿಜನ್ ವೇಕೆನ್ಸಿಗಳನ್ನು ತಗ್ಗಿಸಿದಾಗ, ಅವುಗಳ ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್ ಸುಮಾರು 2.5%ಗೆ ಹೆಚ್ಚಳಗೊಂಡಿದ್ದನ್ನು ಅವರ ತಂಡದವರು ಖಚಿತಪಡಿಸಿಕೊಂಡಿದ್ದಾರೆ (ಇದರ ಫಲಿತಾಂಶಗಳು ಇನ್ನು ಪ್ರಕಟವಾಗಬೇಕಿದೆ). ಜೊತೆಗೆ, ಪೀಜೋಸೆರಾಮಿಕ್ ವಸ್ತುಗಳಲ್ಲಿ ‘ಬಾಗುವಿಕೆ’ಗೆ ಸಂಬಂಧಿಸಿದಂತೆ ತಂಡವು ದೃಢಪಡಿಸಿಕೊಂಡ ಹೊಸ ಅಂಶಗಳು ಮಾನೋಲಿಥ್ ಕ್ಯಾಂಟಿಲಿವರ್ ಗಳ ವಿನ್ಯಾಸದಲ್ಲಿ ಕೂಡ ಉಪಯೋಗಕರ ಆಗಬಲ್ಲವು.

ಪೀಜೋಸೆರಾಮಿಕ್ ಗಳನ್ನು ಹೇಗೆ ತಯಾರಿಸಲಾಗುತ್ತದೆ ಹಾಗೂ ಪರೀಕ್ಷೆಗೆ ಒಳಪಡಿಸಲಾಗುತ್ತದೆ ಎಂಬ ಬಗ್ಗೆ ಪುನರಾವಲೋಕನದ ಅಗತ್ಯವನ್ನು ಈ ಅಧ್ಯಯನದ ಅಂಶಗಳು ಒತ್ತಿ ಹೇಳುತ್ತವೆ. ನಿರ್ದಿಷ್ಟ ದಪ್ಪಕ್ಕಿಂತ ಕಡಿಮೆ ಗಾತ್ರದಲ್ಲಿ ‘ಎಲೆಕ್ಟ್ರೊಸ್ಟ್ರೇನ್’ ಹೇಗೆ ಉಂಟಾಗುತ್ತದೆ ಎಂಬ ಬಗ್ಗೆ ನಮಗೆ ಗೊತ್ತಿರುವಂತದ್ದು ಎಷ್ಟು ಕಡಿಮೆ ಮಾತ್ರ ಎಂಬುದನ್ನೂ ಇದು ಸೂಚಿಸುತ್ತದೆ ಎನ್ನುತ್ತಾರೆ ಸಂಶೋಧಕರು. “ಅಂತಹ ಸಹಜವಲ್ಲದ ಅನಿರೀಕ್ಷಿತ ವರ್ತನೆಯನ್ನು ವಿವರಿಸಲು ನಾವು ಹೊಸ ವಿಧಾನಗಳನ್ನು ಕಂಡುಕೊಳ್ಳಬೇಕಿದೆ” ಎನ್ನುತ್ತಾರೆ ಗೋವಿಂದ ದಾಸ್ ಅಧಿಕಾರಿಯವರು.

ಉಲ್ಲೇಖ:

ಅಧಿಕಾರಿ ಜಿಡಿ, ಅಡುಕ್ಕಡನ್ ಎ. ಮುಲೇತ ಜಿಜೆ, ಮೋನಿಕಾ, ಸಿಂಗ್ ಆರ್, ಸಿಂಗ್ ಡಿಎನ್, ಲುಒ ಎಚ್, ಟೀನಾ ಜಿ.ಎ, ಜೈಲ್ಸ್, ಚೆಚ್ಲಾ ಎಸ್, ಡೇನಿಯಲ್ಸ್ ಜೆ, ರಂಜನ್ ಆರ್. Longitudinal strain enhancement and bending deformations in piezoceramics, Nature (2025). https://www.nature.com/articles/s41586-024-08292-1

ಸಂಪರ್ಕ:

ರಾಜೀವ್ ರಂಜನ್

ಪ್ರಾಧ್ಯಾಪಕರು

ಮಟೀರಿಯಲ್ಸ್ ಎಂಜಿನಿಯರಿಂಗ್ ವಿಭಾಗ (ಎಂಎಟಿಇ)

ಭಾರತೀಯ ವಿಜ್ಞಾನ ಸಂಸ್ಥೆ (ಐ.ಐ.ಎಸ್.ಸಿ.) ಇಮೇಲ್: rajeev@iisc.ac.in

ಫೋನ್: +91-80-2293 2989

ಪರ್ತಕರ್ತರ ಗಮನಕ್ಕೆ:

ಅ) ಈ ಪತ್ರಿಕಾ ಪ್ರಕಟಣೆಯನ್ನು ಅಥವಾ ಇದರ ಯಾವುದೇ ಭಾಗವನ್ನು ಯಥಾವತ್ತಾಗಿ ಸುದ್ದಿಯಾಗಿ ಪ್ರಕಟಿಸಿದರೆ ದಯವಿಟ್ಟು ಐ.ಐ.ಎಸ್.ಸಿ. ಹೆಸರಿನೊಂದಿಗೆ ಪ್ರಕಟಿಸಿ.

ಆ) ಐ.ಐ.ಎಸ್.ಸಿ. ಪತ್ರಿಕಾ ಪ್ರಕಟಣೆಗಳಿಗೆ ಸಂಬಂಧಿಸಿದಂತೆ ಏನಾದರೂ ಪ್ರಶ್ನೆಗಳಿದ್ದರೆ ದಯವಿಟ್ಟು news@iisc.ac.in ಅಥವಾ pro@iisc.ac.in ಗೆ ಬರೆಯಿರಿ.

From birth to bite: How snake venom varies with age

- Rohini Subrahmanyam

Adult Russell’s viper (Photo: Kartik Sunagar)

Snake venom has evolved into a complex cocktail of chemical killers, with remarkable diversity across different snake species. Even the same snake species can face different evolutionary and ecological pressures over time, which can change the potency of its venom.

In a recent study published in BMC Biology, Kartik Sunagar, Associate Professor at the Evolutionary Venomics Lab, Center for Ecological Sciences, IISc, and collaborators explored how the evolutionary ecology of two snake species shapes their venom as they age. The team focused on two clinically relevant venomous snakes in India, the Russell’s viper (Daboia russelii) and the spectacled cobra (Naja naja) – both responsible for a distressing number of deaths and disabilities.

The researchers maintained more than 200 snakes of the two species in captivity, to source venom from them at different stages of the snakes’ lives. They then performed several experiments to check how the composition, activity, and toxicity of the venom changes over time as these snakes change their diet from feeding on one prey to another.

Russell’s viper neonate (Photo: Kartik Sunagar)

Interestingly, the toxicity of the two snakes’ venom varied based on its ontogeny – at which stage of life it was sourced from. In the Russell’s viper, newborns had considerably higher toxicity against mammals and reptiles, as compared to juveniles and adult snakes. On the other hand, the toxicity levels of the cobra venom remained the same over the course of its development. The latter could, however, bind strongly to receptors found in the cell surface of various prey animals, most likely to make up for its lack of ontogenic variation, the researchers suggest. The results provide a glimpse into the evolutionary arms race between prey and predator, and how snakes have adapted and developed effective venom concoctions.

The findings of the study can not only help us better understand how snake venom diversity may have evolved, but also aid us in developing more effective snakebite treatments, which is also a major theme of the lab.

REFERENCE:

Senji Laxme RR, Khochare S, Bhatia S, Martin G, Sunagar K, From birth to bite: the evolutionary ecology of India's medically most important snake venoms, BMC Biology (2024).

https://doi.org/10.1186/s12915-024-01960-8

LAB WEBSITE:

https://www.venomicslab.com/

Engineered biocatalyst for making "drop-in" biofuels

28 June 2024

- Pratibha Gopalakrishna

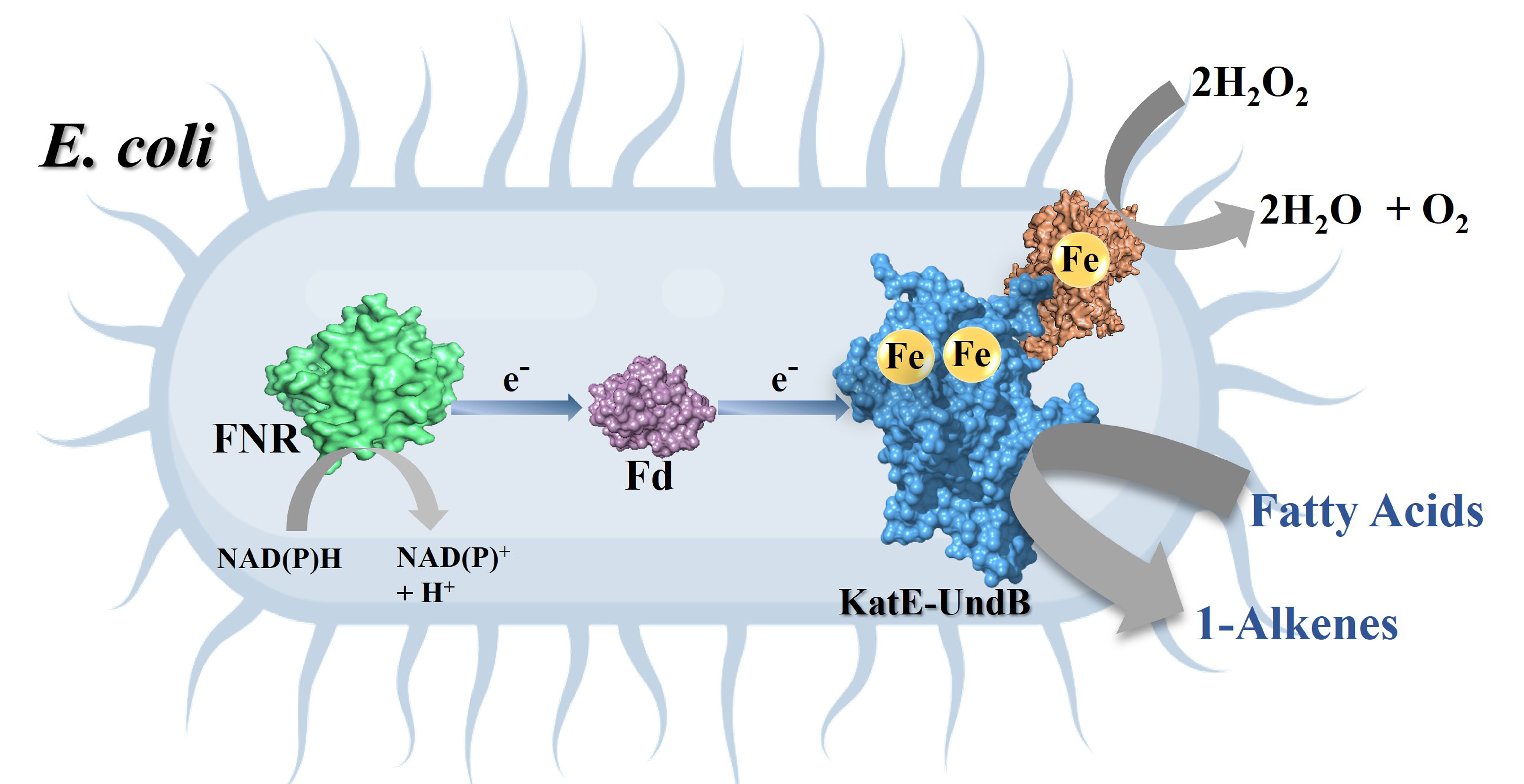

Researchers at the Department of Inorganic and Physical Chemistry (IPC), Indian Institute of Science (IISc), have developed an enzymatic platform that can efficiently transform naturally abundant and inexpensive fatty acids to valuable hydrocarbons called 1-alkenes, which are promising biofuels.

Given the finite availability and polluting nature of fossil fuels, scientists are increasingly exploring sustainable fuel pathways that involve compounds called hydrocarbons. They show great potential as “drop-in” biofuels, which can be blended and used with existing fuels and infrastructure. These hydrocarbons can potentially be synthesised on a large scale using microorganism “factories”. Enzymes that help mass-produce these hydrocarbons are therefore highly sought after. Hydrocarbons are also widely used in polymer, detergent and lubricant industries.

In a previous study, the IISc team purified and characterised an enzyme called UndB, bound to the membranes of living cells, especially certain bacteria. It can convert fatty acids to 1-alkenes at the fastest rate currently possible. But the team found that the process was not very efficient – the enzyme would become inactivated after just a few cycles. When they investigated further, they realised that H2O2 – a byproduct of the reaction process – was inhibiting UndB.

In the current study published in Science Advances, the team circumvented this challenge by adding another enzyme called catalase to the reaction mix. “The catalase degrades the H2O2 that is produced,” explains Tabish Iqbal, first author of the study and PhD student at IPC. Adding catalase, he says, enhanced the activity of the enzyme 19-fold, from 14 to 265 turnovers (turnover indicates the number of active cycles an enzyme completes before getting inactivated).

Engineered whole cell biocatalyst for efficient 1-alkene production (Image: Tabish Iqbal)

Excited by this finding, the team decided to create an artificial fusion protein combining UndB with catalase, by introducing a fused genetic code via carriers called plasmids into E. coli bacteria. Given the right conditions, these E. coli would then act as a “whole cell biocatalyst”, converting fatty acids and churning out alkenes.

However, there were several challenges. Being a membrane protein, UndB is extremely challenging to work with. Beyond a certain concentration, it can be toxic to bacterial cells. Membrane proteins like UndB are also not soluble in water, making it hard to maintain the right conditions for studying them.

To improve the efficiency of their chimeric protein, the team tested the effect of various “redox partner” proteins that help shuttle electrons to UndB during the conversion of fatty acids to alkenes. They found that proteins called ferredoxin and ferredoxin reductase, along with nicotinamide adenine dinucleotide phosphate (NADPH), were able to supply electrons most efficiently. On incorporating these in the genetically modified E. coli and feeding fatty acids, the efficiency of conversion rose up to 95%.

A key advantage of this biocatalyst is that UndB is very specific and does not produce any unwanted side products – pure 1-alkene is the only product, says Debasis Das, Assistant Professor at IPC and corresponding author. “1-alkenes can directly be used as biofuels,” he adds.

From left to right: Subhashini Murugan, Debasis Das, Tabish Iqbal (Photo: Jayaprakash K)

The team found that their biocatalyst could convert a wide range of fatty acids containing different types of carbon chains to 1-alkene. They also showed that the biocatalyst can produce styrene, an important commodity in chemical and polymer industries.

The team has applied for a patent for their engineered protein and whole cell biocatalyst. They are also looking for industry collaborators to scale up the platform for mass-production.

“Our platform can be efficiently used to generate a large number of 1-alkenes that are valuable in biotechnology and polymer industries,” says Das.

REFERENCE:

Iqbal T, Murugan S, Das D, A chimeric membrane enzyme and an engineered whole-cell biocatalyst for efficient 1-alkene production, Science Advances (2024).

CONTACT:

Debasis Das

Assistant Professor

Department of Inorganic and Physical Chemistry (IPC)

Indian Institute of Science (IISc)

Email: debasisdas@iisc.ac.in

Phone: +91 80 2293 3002

Website: https://sites.google.com/view/ddlaboratory/home

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.

IISc’s Convocation to be held on 15 July 2024

12 July 2024

The Indian Institute of Science (IISc) will host this year’s convocation on Monday, 15 July 2024, from 11:00 am at the JN Tata auditorium to confer degrees upon students who are graduating this year.

Viswanathan Anand, five-time world champion in chess and Padma Vibhushan awardee will be the Chief Guest of the event. The Guest of Honour will be Senapathy ‘Kris’ Gopalakrishnan, Chair, IISc Council.

A total of 1,136 degrees will be awarded during the ceremony, with 465 Research degrees, 571 Master’s course degrees and 100 undergraduate degrees conferred on students. Gold medals will also be awarded to 57 students for academic excellence.

IISc currently offers PhD and Integrated PhD programmes, several Master’s programmes (MTech, MTech (Res), MDes, MMgmt), a four-year Bachelor of Science (Research) programme and a BTech in Mathematics and Computing.

Turning infrared light visible

20 June 2024

- Ullas

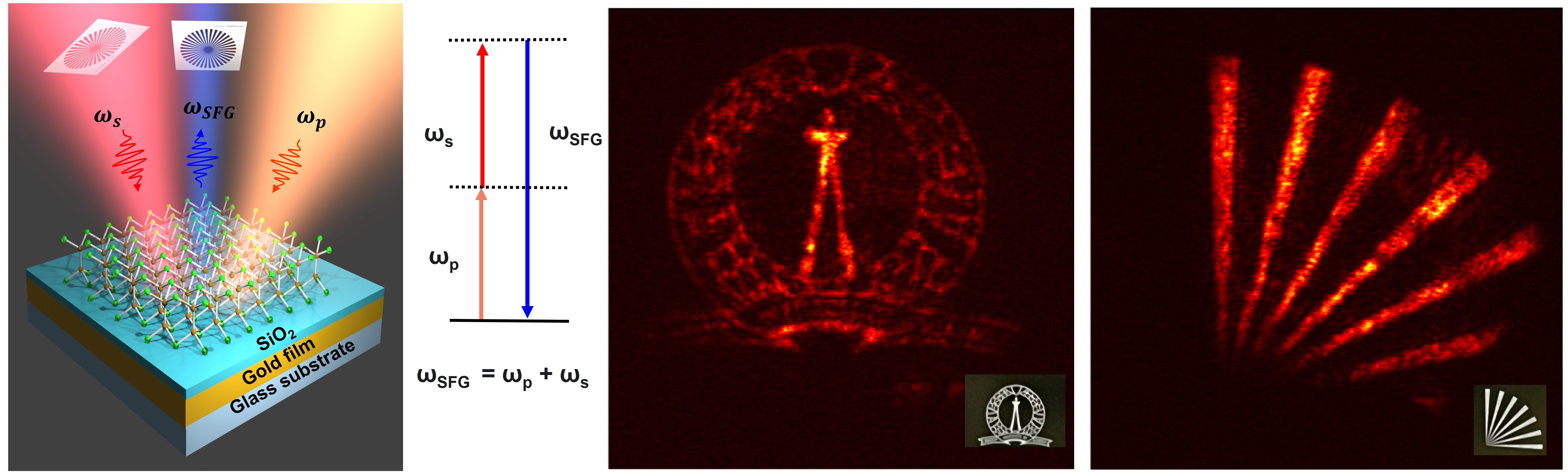

From Left to Right: Schematic of the nonlinear optical mirror used for up-conversion imaging. Energy diagram showing the sum frequency generation process used for up-conversion. Representative up-converted images of IISc logo and spokes where the object pattern at 1550 nm is upconverted to 622 nm wavelength (Images: Jyothsna KM)

The human eye can only see light at certain frequencies (called the visible spectrum), the lowest of which constitutes red light. Infrared light, which we can’t see, has an even lower frequency than red light. Researchers at the Indian Institute of Science (IISc) have now fabricated a device to increase or “up-convert” the frequency of short infrared light to the visible range.

Up-conversion of light has diverse applications, especially in defence and optical communications. In a first, the IISc team used a 2D material to design what they call a non-linear optical mirror stack to achieve this up-conversion, combined with widefield imaging capability. The stack consists of multilayered gallium selenide fixed to the top of a gold reflective surface, with a silicon dioxide layer sandwiched in between.

Traditional infrared imaging uses exotic low-energy bandgap semiconductors or micro-bolometer arrays, which usually pick up heat or absorption signatures from the object being studied. Infrared imaging and sensing is useful in diverse areas, from astronomy to chemistry. For example, when infrared light is passed through a gas, sensing how the light changes can help scientists tease out specific properties of the gas. Such sensing is not always possible using visible light.

However, existing infrared sensors are bulky and not very efficient. They are also export-restricted because of their utility in defence. There is, therefore, a critical need to develop indigenous and efficient devices.

The method used by the IISc team involves feeding an input infrared signal along with a pump beam onto the mirror stack. The nonlinear optical properties of the material constituting the stack result in a mixing of the frequencies, leading to an output beam of increased (up-converted) frequency, but with the rest of the properties intact. Using this method, they were able to up-convert infrared light of wavelength around 1550 nm to 622 nm visible light. The output light wave can be detected using traditional silicon-based cameras.

“This process is coherent – the properties of the input beam are preserved at the output. This means that if one imprints a particular pattern in the input infrared frequency, it automatically gets transferred to the new output frequency,” explains Varun Raghunathan, Associate Professor in the Department of Electrical Communication Engineering (ECE) and corresponding author of the study published in Laser & Photonics Reviews.

Lead author Jyothsna KM aligning optical beams for up-conversion experiments (Photo: Harinee Natarajan)

The advantage of using gallium selenide, he adds, is its high optical nonlinearity, which means that a single photon of infrared light and a single photon of the pump beam could combine to give a single photon of light with up-converted frequency. The team was able to achieve the up-conversion even with a thin layer of gallium selenide measuring just 45 nm. The small size makes it more cost-effective than traditional devices that use centimetre-sized crystals. Its performance was also found to be comparable to current state-of-the-art up-conversion imaging systems.

Jyothsna K Manattayil, PhD student at ECE and first author, explains that they used a particle swarm optimisation algorithm to speed up the calculation of the right thickness of layers needed. Depending on the thickness, the wavelengths that can pass through gallium selenide and get up-converted will vary. This means that the material thickness needs to be tweaked depending on the application. “In our experiments, we have used infrared light of 1550 nm and a pump beam of 1040 nm. But that doesn’t mean that it won’t work for other wavelengths,” she says. “We saw that the performance didn’t drop for a wide range of infrared wavelengths, from 1400 nm to 1700 nm.”

Going forward, the researchers plan to extend their work to up-convert light of longer wavelengths. They are also trying to improve the efficiency of the device by exploring other stack geometries.

“There is a lot of interest worldwide in doing infrared imaging without using infrared sensors. Our work could be a gamechanger for those applications,” says Raghunathan.

REFERENCE:

Manattayil JK, Lal Krishna AS, Asish Prosad A, Bag U, Biswas R, Raghunathan V, 2D Material Based Nonlinear Optical Mirror for Widefield Up-Conversion Imaging from Near Infrared to Visible Wavelengths, Laser & Photonics Reviews (2024).

CONTACT:

Varun Raghunathan

Associate Professor

Department of Electrical Communication Engineering (ECE)

Indian Institute of Science (IISc)

Email: varunr@iisc.ac.in

Phone: +91-80-2293-3473

Website: https://sites.google.com/site/varunr196/home

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.

Sustainable removal of heavy metal contaminants from groundwater

11 June 2024

- Sandeep Menon

The adsorbent stage (left) and remediation stage (right) in the pilot system in the lab (Photo courtesy: S3 lab, CST, IISc)

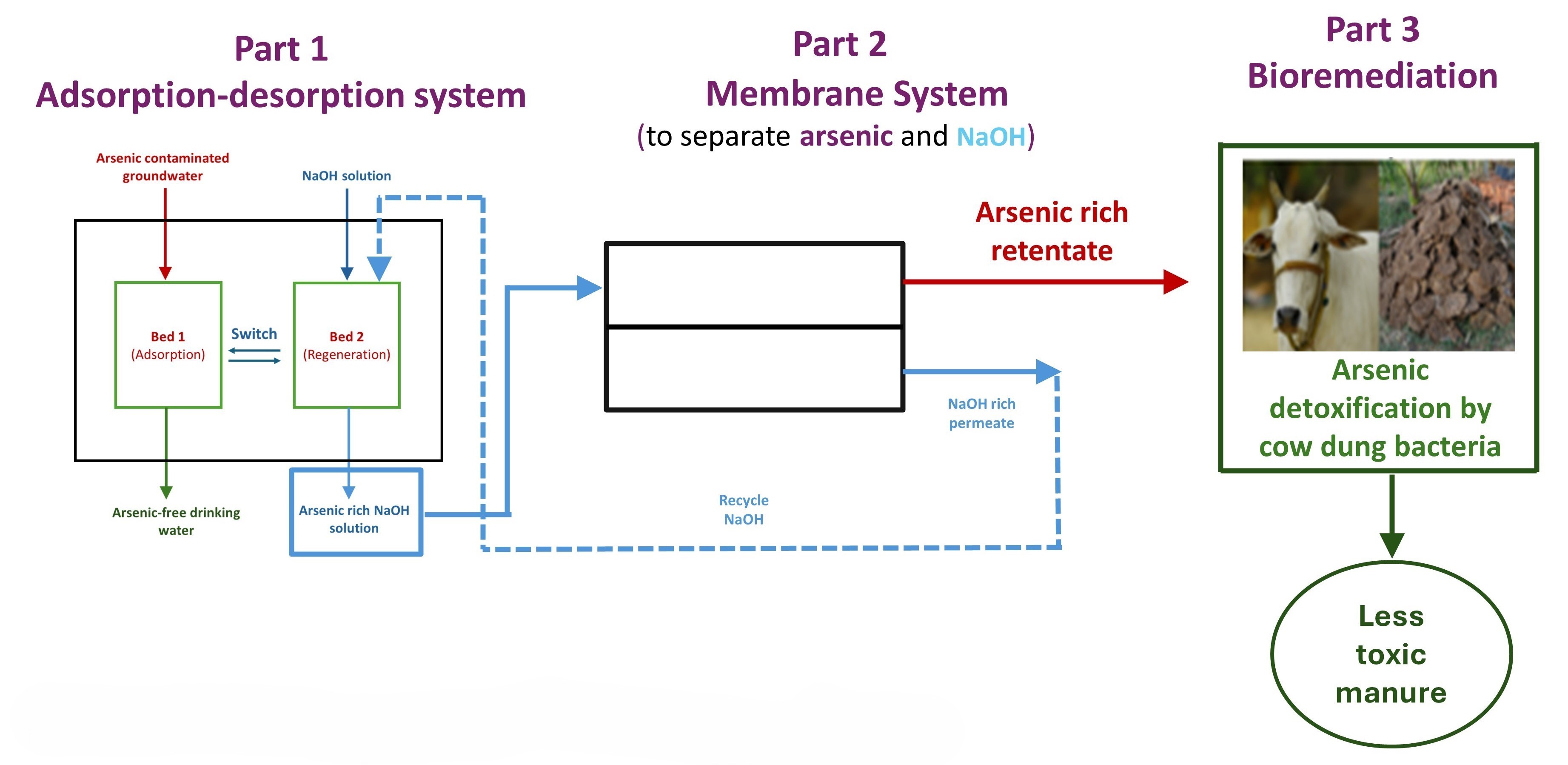

Researchers at the Centre for Sustainable Technologies (CST), Indian Institute of Science (IISc) have developed a novel remediation process for removing heavy metal contaminants such as arsenic from groundwater. The three-step method, which is patent-pending, also ensures that the removed heavy metals are disposed of in an environment-friendly and sustainable manner, instead of sending untreated heavy metal-rich sludge to landfills from where they can potentially re-enter groundwater.

“In every technology that exists, you can take out arsenic and provide clean water. However, after you remove the arsenic, you must do something about it so that it doesn’t re-enter the environment, and that aspect is not given due consideration in existing methods. Our process was designed to solve this problem,” says Yagnaseni Roy, Assistant Professor at CST, whose lab has developed the method.

According to reports, 113 districts in 21 states in India have arsenic levels above 0.01 mg per litre while 223 districts in 23 states have fluoride levels above 1.5 mg per litre, which are beyond the permissible limits set by the Bureau of Indian Standards and the World Health Organisation (WHO). These contaminants can significantly affect human and animal health, necessitating their efficient removal and safe disposal.

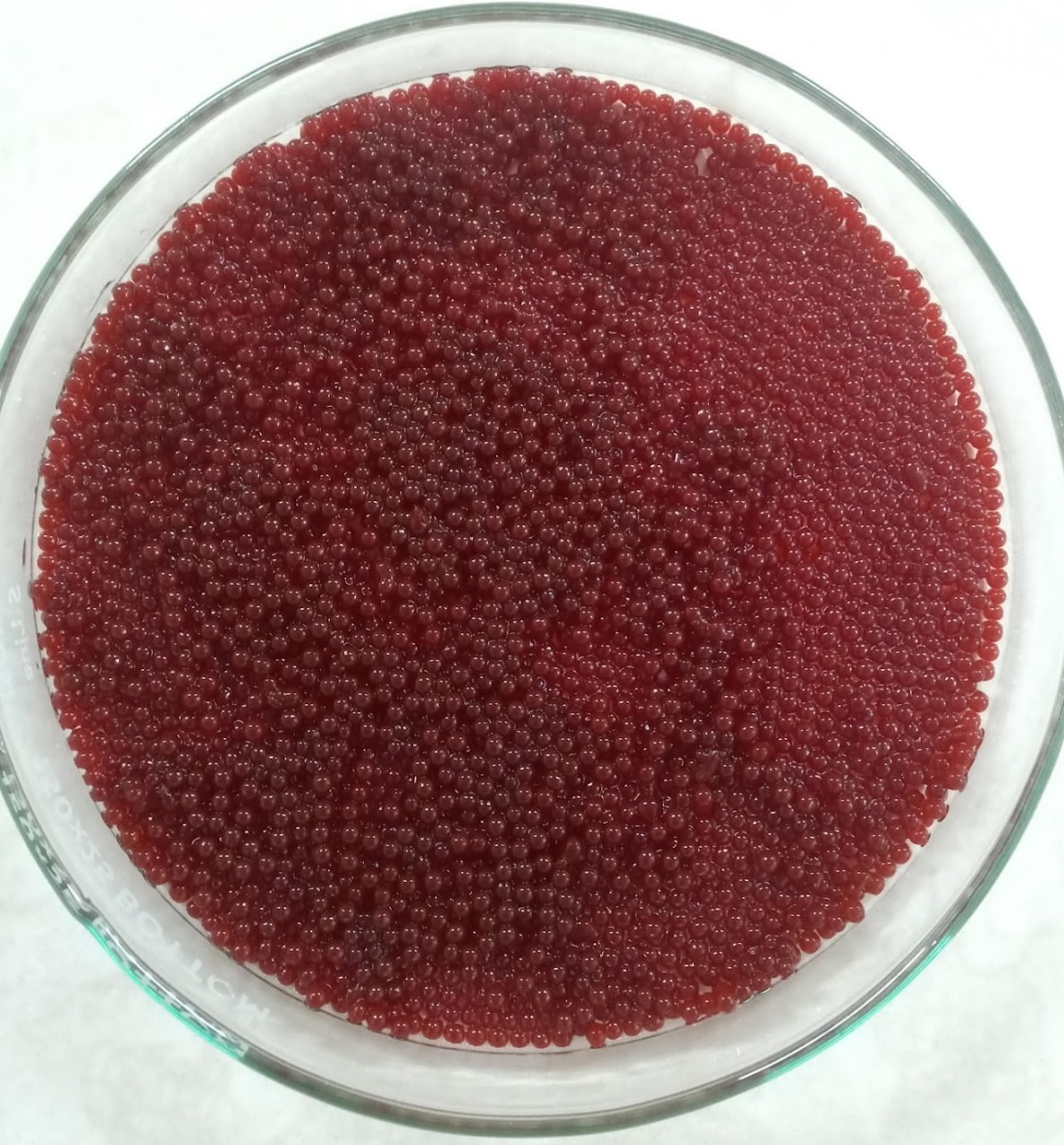

The first step in the process developed by the IISc team involves passing the contaminated water through a bed of biodegradable adsorbent made of chitosan – a fibrous substance obtained from crustaceans – doped with bimetallic (Fe and Al) hydroxide/oxyhydroxide. The adsorbent bed grabs the toxic inorganic arsenic through electrostatic forces and complex formation between arsenic and the adsorbent. A novel aspect of the technology is that the alkaline wash – used to repeatedly regenerate the adsorbent bed after its saturation – is recycled within the scheme.

Close-up view of the adsorbent beads (Photo courtesy: S3 lab, CST, IISc)

In the second step, the alkaline wash solution, which is essentially sodium hydroxide and arsenic in water, is taken to a membrane system to separate the two. While the sodium hydroxide solution (the alkaline wash) is taken back to regenerate the bed, the arsenic concentrated in the other stream is now ready to be taken to the third step: bioremediation. The membrane process serves to concentrate the arsenic ahead of bioremediation.

In the bioremediation step, the toxic inorganic arsenic is converted to low-toxicity organic arsenic via methylation by microbes found in cow dung. This results in a decrease of toxic inorganic arsenic to below the maximum permissible limit specified by WHO standards, within a span of eight days. The remaining cow dung sludge can be safely disposed of in landfills, since the arsenic is locked in it in an organic form.

"On average, these organic species are approximately 50 times less toxic than the inorganic form present in groundwater,” says Roy.

The system can also be adapted to remove fluoride, with the last step changed to precipitation to form calcium fluoride, which has very low solubility in water. Roy’s team is currently checking the feasibility of tackling other heavy metals using the same system.

Schematic of the process (Image courtesy: S3 lab, CST, IISc)

The system is easy to assemble and operate. Manufacturing the adsorbent material involves a simple recipe. In the lab, a small pilot-scale adsorption column system was able to generate safe drinking water (by WHO standards) for two people for three days. The researchers have been working with INREM Foundation and Earthwatch, both NGOs, to deploy and test these systems in rural areas such as Bhagalpur in Bihar and Chikkaballapur in Karnataka.

According to the researchers, such a system would work best at the community level.

“The collection of waste, maintenance and operation are easier on a community scale than individual houses. The maintenance is simple enough that it can be operated by people in the community itself, which will help with income generation for people operating the system,” says Rasmi Mohan T, PhD student at CST who has worked on the process. “For a larger scale, we might need funding to take it to various parts of the country.”

Along with Roy and Mohan, Master’s student Subhash Kumar and post-doctoral fellow Manamohan Tripathy have also been involved in developing the scheme at both lab and pilot scales.

CONTACT:

Yagnaseni Roy

Assistant Professor

Centre for Sustainable Technologies (CST)

Indian Institute of Science (IISc)

Email: yroy@iisc.ac.in

Phone: 080 2293 3016

Website: https://www.s3iisc.com/home

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.

Novel 3D hydrogel culture to study TB infection and treatment

25 June 2024

- Pratibha Gopalakrishna

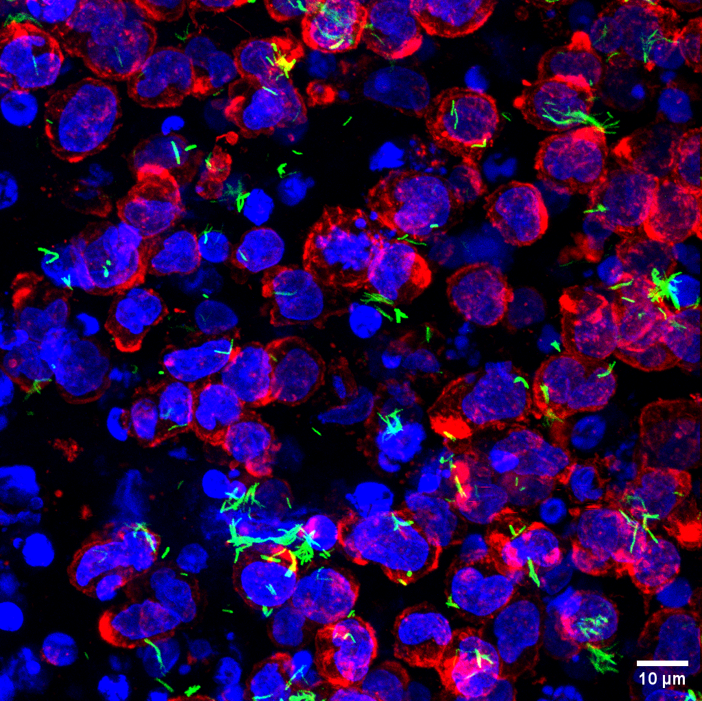

Human immune cells (nucleus: blue, cell boundary: red) with Mycobacterium tuberculosis (green) in the collagen hydrogels (Image: Vijaya V Vaishnavi)

Researchers from the Department of Bioengineering (BE), Indian Institute of Science (IISc), have designed a novel 3D hydrogel culture system that mimics the mammalian lung environment. It provides a powerful platform to track and study how tuberculosis bacteria infect lung cells and test the efficacy of therapeutics used to treat TB.

Mycobacterium tuberculosis (Mtb) is a dangerous pathogen. In 2022, it affected 10.6 million people and caused 1.3 million deaths, according to the WHO. “It is a very old bug, and it has evolved with us quite a bit,” says Rachit Agarwal, Associate Professor at BE and corresponding author of the study published in Advanced Healthcare Materials. Mtb primarily infects the lungs.

Current culture models used to study Mtb infection have several limitations. They are typically culture plates that are monolayered and do not accurately mimic the 3D microenvironment inside the lungs. The microenvironment experienced by the cells in such 2D culture is vastly different from the actual extracellular matrix (ECM) surrounding lung tissue. “In a tissue culture plate, there are no ECM molecules, and even if a very thin layer of ECM is coated on these plates, the lung cells 'see' the ECM on one side at best,” explains Vishal Gupta, PhD student at BE and first author.

The 2D culture plates are also extremely hard compared to the soft lung tissues. “You are looking at a rock versus a pillow,” explains Agarwal.

He and his team have now designed a novel 3D hydrogel culture made of collagen, a key molecule present in the ECM of lung cells. Collagen is soluble in water at a slightly acidic pH. As the pH is increased, the collagen forms fibrils which cross-link to form a gel-like 3D structure. At the time of gelling, the researchers added human macrophages – immune cells involved in fighting infection – along with Mtb. This entrapped both the macrophages and the bacteria in the collagen and allowed the researchers to track how the bacteria infect the macrophages.

Vijaya V Vaishnavi (left) and Vishal K Gupta (right), lead authors of the study (Photo: Bhagyashree Padhan)

The team tracked how the infection progressed over 2-3 weeks. What was surprising was that the mammalian cells stayed viable for three weeks in the hydrogel – current cultures are only able to sustain them for 4-7 days. “This makes it more attractive because Mtb is a very slow-growing pathogen inside the body,” says Agarwal.

Next, the researchers carried out RNA sequencing of the lung cells that grew in the hydrogel, and found that they were more similar to actual human samples, compared to those in traditional culture systems.

The team also tested the effect of pyrazinamide – one of the four most common drugs given to TB patients. They found that even a small amount (10 µg/ml) of the drug was quite effective in clearing out Mtb in the hydrogel culture. Previously, scientists have had to use large doses of the drug – much higher compared to concentrations achieved in patients – to show that it is effective in tissue culture. “Nobody has shown that this drug works in clinically relevant doses in any culture systems … Our setup reinforces the fact that the 3D hydrogel mimics the infection better,” explains Agarwal.

Agarwal adds that they have already filed an Indian patent for their 3D culture, which can be scaled up by industries and used for drug testing and discovery. “The idea was to keep it quite simple so that other researchers can replicate this,” he adds.

Moving forward, the researchers plan to mimic granulomas – clusters of infected white blood cells – in their 3D hydrogel culture to explore why some people have latent TB, while others show aggressive symptoms. Gupta says that the team is also interested in understanding the mechanism of action of pyrazinamide, which may help discover new drugs that are more or just as efficient.

REFERENCE:

Gupta VK, Vaishnavi VV, Arrieta-Ortiz ML, Abhirami PS, Jyothsna KM, Jeyasankar S, Raghunathan V, Baliga NS, Agarwal R, 3D Hydrogel Culture System Recapitulates Key Tuberculosis Phenotypes and Demonstrates Pyrazinamide Efficacy, Advanced Healthcare Materials (2024).

https://doi.org/10.1002/adhm.202304299

CONTACT:

Rachit Agarwal

Associate Professor

Department of Bioengineering (BE)

Indian Institute of Science (IISc)

Email: rachit@iisc.ac.in

Phone: +91-80-2293-3626

Website: https://be.iisc.ac.in/~rachit/

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.

Novel method for mass production of recombinant proteins

– Pratibha Gopalakrishna

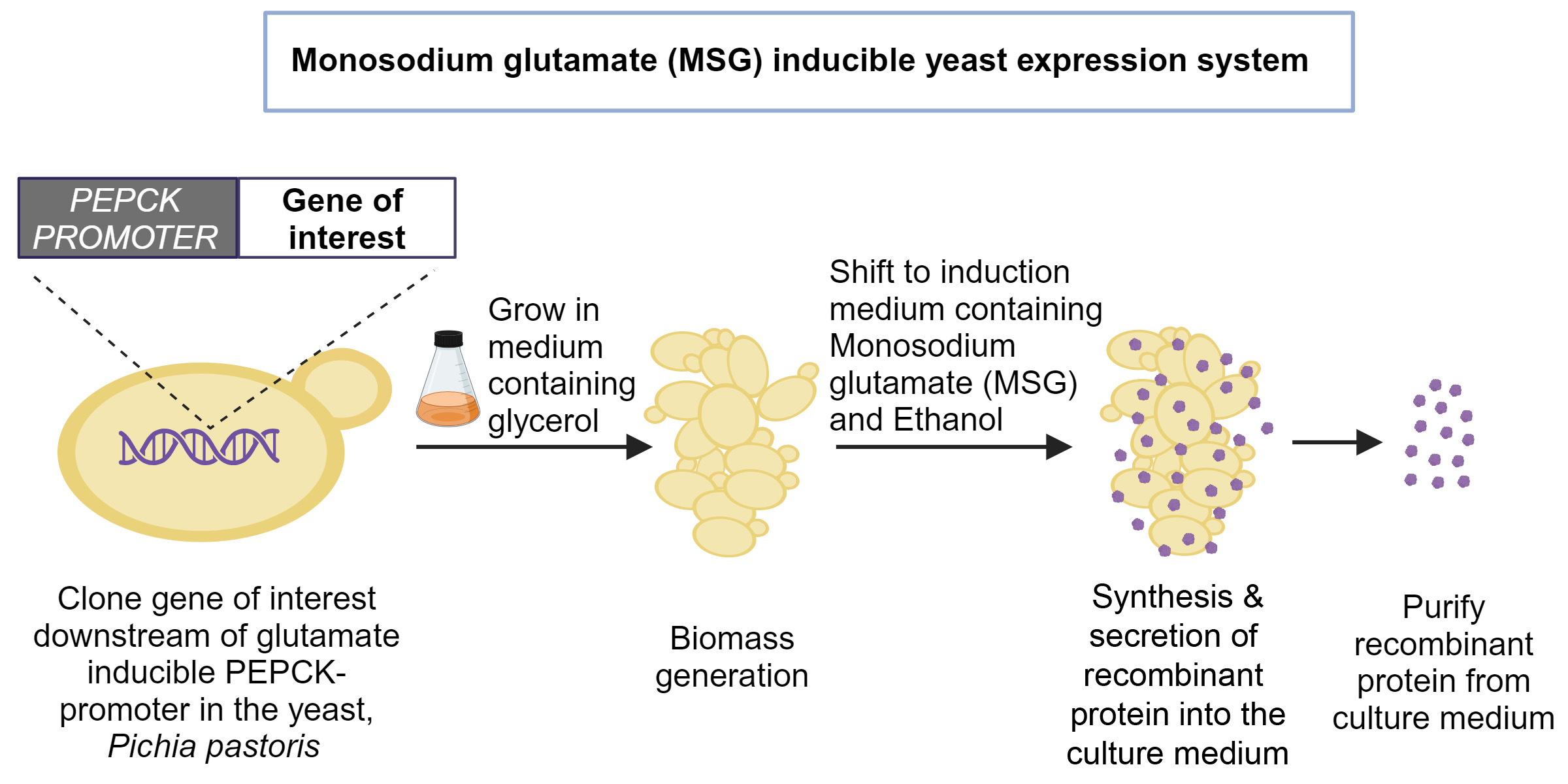

Illustration of the new process developed by PN Rangarajan’s lab (Image courtesy: Neetu Rajak)

Mass production of recombinant proteins using yeast cell “factories” needs methanol, a compound that requires safe handling, carries the risk of catching fire, and sometimes produces harmful byproducts. Researchers at the Department of Biochemistry (BC), Indian Institute of Science (IISc), have now developed an alternative safer process that instead relies on a common food additive called mono-sodium glutamate (MSG).

Recombinant proteins, such as vaccine antigens, insulin and monoclonal antibodies, are mass-produced by growing modified bacterial, viral or mammalian cells in large bioreactors. The most widely used organism is the yeast Pichia pastoris (now called Komagataella phaffii). It contains a unique promoter – a specific gene region which can be activated by methanol. This promoter codes for an enzyme called alcohol oxidase (AOX).

To mass-produce a recombinant protein, the gene coding for that protein is spliced into the yeast genome right next to the AOX promoter. The yeast cells are then fed glycerol or glucose as the carbon source. Once enough cells have formed, methanol is added, which then activates the AOX promoter, and the cells start producing the recombinant protein in copious amounts.

Most industries use this methanol-induced process for producing recombinant proteins. However, methanol is highly flammable and hazardous, requiring stringent safety precautions, points out PN Rangarajan, Professor at BC and corresponding author of the study published in Microbial Cell Factories. Methanol also metabolises to form hydrogen peroxide which can induce oxidative stress in the yeast cells or damage the recombinant proteins.

To solve this problem, Trishna Dey, a former PhD student at BC, started looking for alternatives. After an extensive search, the team found that mono-sodium glutamate (MSG), a USFDA approved food additive, can activate a different promoter in the yeast genome that codes for an enzyme called phosphoenolpyruvate carboxykinase (PEPCK). Activating this promoter with MSG led to protein production similar to methanol activation of the AOX promoter.

Optimising the cell culture medium for this new and untested process was challenging, says Neetu Rajak, first author and PhD student at BC. For a long time, the yeast cells grew poorly in shake flasks and produced very little recombinant protein. “There was a time when we almost gave up because we thought it was not going to work,” recalls Rangarajan.

Top: Yash Sharma, Neetu Rajak, and Vedanth Bellad; Bottom right: PN Rangarajan, Bottom left: Trishna Dey (Photo courtesy: Neetu Rajak)

The group eventually figured out that using MSG alone was not enough. Vedanth Bellad and Yash Sharma, project assistants at BC and co-authors, explain that they tried supplementing the culture with various other compounds, until one finally did the trick: ethanol. Adding ethanol helped the cells grow faster, which increased the biomass and the amount of recombinant protein produced. Ethanol is also safer for yeast cells compared to methanol, as it does not produce toxic byproducts when broken down.

To test their process, the team tried producing the SARS-CoV-2 receptor binding domain – a widely-used vaccine antigen that has been successfully expressed in yeast and mammalian cells. They found that their new expression system produced twice the amount of antigen compared to the methanol-induced process.

The researchers hope that this novel and indigenous expression system can be used in biotech industries to mass-produce valuable proteins including milk and egg proteins, baby food supplements and nutraceuticals, apart from therapeutic molecules. An Indian patent has been granted for the expression system and a US patent has been filed. The team is also looking for industry collaborators to scale up the system for mass production.

REFERENCE:

Rajak N, Dey T, Sharma Y, Bellad V, Rangarajan PN, Unlocking Nature’s Toolbox: glutamate-inducible recombinant protein production from the Komagatella phaffii PEPCK promoter, Microbial Cell Factories (2024).

CONTACT:

PN Rangarajan

Professor

Department of Biochemistry

Indian Institute of Science (IISc)

Email: pnr@iisc.ac.in

Phone: 080-22932540

Website: https://biochem.iisc.ac.in/p-n-rangarajan.php

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.

IISc physicists find a new way to represent ‘pi’

18 June 2024

While investigating how string theory can be used to explain certain physical phenomena, scientists at the Indian Institute of Science (IISc) have stumbled upon on a new series representation for the irrational number pi. It provides an easier way to extract pi from calculations involved in deciphering processes like the quantum scattering of high-energy particles.

The new formula under a certain limit closely reaches the representation of pi suggested by Indian mathematician Sangamagrama Madhava in the 15th century, which was the first ever series for pi recorded in history. The study was carried out by Arnab Saha, a post-doc and Aninda Sinha, Professor at Centre for High Energy Physics (CHEP), and published in Physical Review Letters.

“Our efforts, initially, were never to find a way to look at pi. All we were doing was studying high-energy physics in quantum theory and trying to develop a model with fewer and more accurate parameters to understand how particles interact. We were excited when we got a new way to look at pi,” Sinha says.

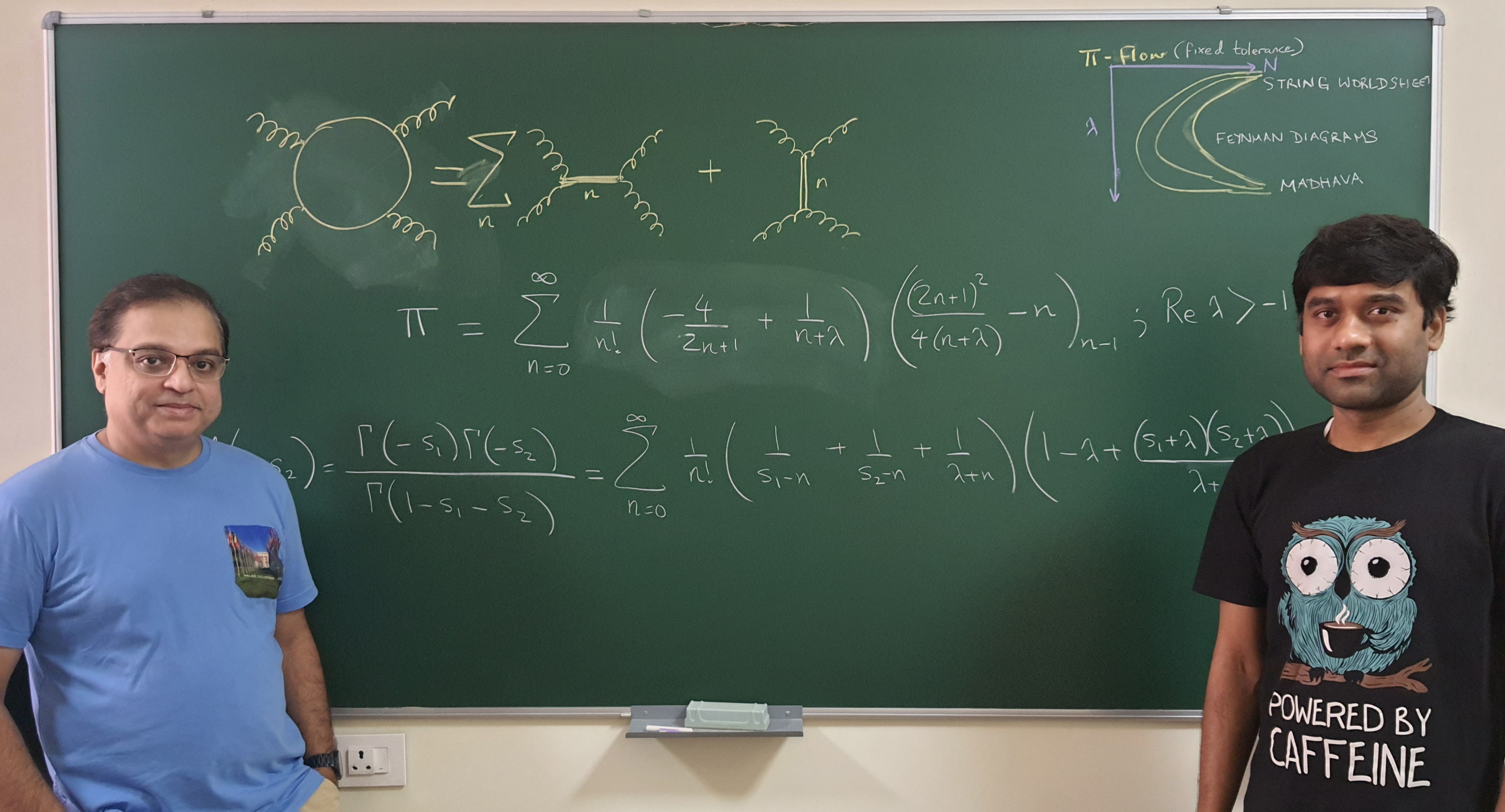

Aninda Sinha (left) and Arnab Saha (right) (Photo: Manu Y)

Sinha’s group is interested in string theory – the theoretical framework that presumes that all quantum processes in nature simply use different modes of vibrations plucked on a string. Their work focuses on how high energy particles interact with each other – such as protons smashing together in the Large Hadron Collider – and in what ways we can look at them using as few and as simple factors as possible. This way of representing complex interactions belongs to the category of “optimisation problems.” Modelling such processes is not easy because there are several parameters that need to be taken into account for each moving particle – its mass, its vibrations, the degrees of freedom available for its movement, and so on.

Saha, who has been working on the optimisation problem, was looking for ways to efficiently represent these particle interactions. To develop an efficient model, he and Sinha decided to club two mathematical tools: the Euler-Beta Function and the Feynman Diagram. Euler-Beta functions are mathematical functions used to solve problems in diverse areas of physics and engineering, including machine learning. The Feynman Diagram is a mathematical representation that explains the energy exchange that happens while two particles interact and scatter.

What the team found was not only an efficient model that could explain particle interaction, but also a series representation of pi.

In mathematics, a series is used to represent a parameter such as pi in its component form. If pi is the “dish” then the series is the “recipe”. Pi can be represented as a combination of many numbers of parameters (or ingredients). Finding the correct number and combination of these parameters to reach close to the exact value of pi rapidly has been a challenge. The series that Sinha and Saha have stumbled upon combines specific parameters in such a way that scientists can rapidly arrive at the value of pi, which can then be incorporated in calculations, like those involved in deciphering scattering of high-energy particles.

“Physicists (and mathematicians) have missed this so far since they did not have the right tools, which were only found through work we have been doing with collaborators over the last three years or so,” Sinha explains. “In the early 1970s, scientists briefly examined this line of research but quickly abandoned it since it was too complicated.”

Although the findings are theoretical at this stage, it is not impossible that they may lead to practical applications in the future. Sinha points to how Paul Dirac worked on the mathematics of the motion and existence of electrons in 1928, but never thought that his findings would later provide clues to the discovery of the positron, and then to the design of Positron Emission Tomography (PET) used to scan the body for diseases and abnormalities. “Doing this kind of work, although it may not see an immediate application in daily life, gives the pure pleasure of doing theory for the sake of doing it,” Sinha adds.

REFERENCE:

Saha AP, Sinha A, Field theory expansions of string theory amplitudes, Physical Review Letters (2024).

CONTACT:

Aninda Sinha

Professor, Centre for High Energy Physics (CHEP)

Indian Institute of Science (IISc)

Email: asinha@iisc.ac.in

Phone: +91-80-22932851

Website: https://chep.iisc.ac.in/Personnel/asinha.html

NOTE TO JOURNALISTS:

a) If any of the text in this release is reproduced verbatim, please credit the IISc press release.

b) For any queries about IISc press releases, please write to news@iisc.ac.in or pro@iisc.ac.in.

Fujitsu Limited and IISc sign MoU for collaboration in data science

22 May 2024

Fujitsu Limited and Indian Institute of Science (IISc) have signed an MoU to bring together researchers with diverse theoretical and systems backgrounds. The collaboration aims to lay down the algorithmic foundations for the field of data science across the full breadth of scientific issues that arise in the rich and complex processes which use data to make decisions. It will also focus on modeling issues, inferential issues, computational issues, and application-related issues.

The MoU was signed between IISc and Fujitsu Limited on 22 May 2024 at the IISc Bangalore campus. Faculty members Soumyendu Raha and Debnath Pal, Professors at the Department of Computational and Data Sciences, are the Principal Investigators from the IISc side.

The MoU focuses on joint research towards the creation of standards, guidelines and protocols for trustworthy and responsible use of research data. It also focuses on outreach activities to promote knowledge dissemination in the High Performance Computing (HPC) domain. IISc and Fujitsu researchers will work jointly on areas such as high dimensions and spikes; graphs, diffusion maps, and semi-supervised learning; spectral clustering; concentration inequalities; sparse vectors and low-rank matrices; sparse recovery and scarification; stochastic block models and synchronisation problems.

The initiative will emphasise the exploration of new high performance computation paradigms and their realisation. The emerging technological field of joint research in high-performance algorithms will be the thematic core of these efforts, in order to develop effective and useful solutions for data science problems.

CONTACT

IISc Office of Communications | news@iisc.ac.in

Pagination

- Page 1

- Next page